COOL LINER CARRIER eCOOL

with all-electric Carrier eCool unit

- EMISSION FREE OPERATION

- SILENT NIGHT DELIVERY

- ENERGY GENERATION BY AXLE GENERATOR

- EVEN WEIGHT DISTRIBUTION

- OPERATING UNIT ON REFRIGERATED BODY FRONT WALL

For low-noise and low-emission urban refrigerated transport, Krone presents the Cool Liner with Carrier Vector eCool. An axle generator feeds the battery pack with electrical energy. In addition, a 400 V plug-in contact enables operation of the refrigeration system as well as parallel external charging of the battery via shore power.

Technical data

Type

SDR 27 eL4-DS

KING PIN LOAD

12000 kg

AXLE LOAD

27000 kg

ALLOWABLE GROSS WEIGHT

39000 kg

5TH WHEEL HEIGHT

1150 mm

AXLE SPREAD

1310 mm

INTERNAL LENGTH

13311 mm

INTERNAL WIDTH

2495 mm

INTERNAL HEIGHT

2630 mm

Technical data

Type

SDR 27 eL4-DS

KING PIN LOAD

12000 kg

AXLE LOAD

27000 kg

ALLOWABLE GROSS WEIGHT

39000 kg

5TH WHEEL HEIGHT

1150 mm

AXLE SPREAD

1310 mm

INTERNAL LENGTH

13311 mm

INTERNAL WIDTH

2495 mm

INTERNAL HEIGHT

2630 mm

Always a plus on equipment.

Simply inimitable

Optimum air guidance

Stable aluminium profiles ensure the best front wall protection and optimal air flow with their large profile cross-section.

Bolted evaporator guard

Haccp-compliant and removable to aid cleaning.

LED internal lights

The internal lighting of the superstructure is provided by four bright LED lights under the roof.

Continuous chassis

The Cool Liner is equipped with a continuous chassis. Tensile forces are transferred to the chassis, which protects the coffer superstructure during vehicle coupling and uncoupling. The forces involved when docking to the ramp are also absorbed by the chassis.

Flexible air channel

. The flexible, ceiling-mounted air ducts evenly distribute cold air in the trailer and are also suitable for both double deck loading and using a cross partition.

Intelligent door electronics

For added protection, the marker lamps are integrally housed into the rear frame. The door contact switch for the internal lighting reacts without contact and can be combined with KRONE Telematics.

Practical rear gantry

The stainless steel rear gantry has been designed to be suitable for both docks and ramps. Door hinges are recessed at the sides to allow an optimal door opening angle. As an option, four door locks are available.

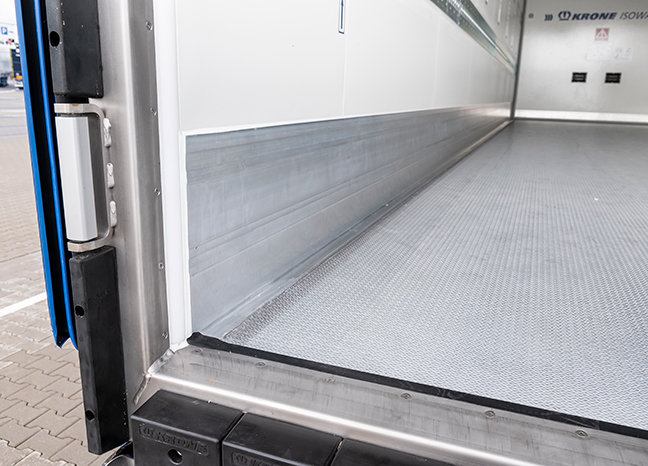

Water-tight kick strips

The aluminium kick strip is welded to the side walls and sealed watertight with the one-piece low noise aluminium floor.

To achieve a high level of sustainability, especially for inner-city refrigerated transport, Krone has equipped the Cool Liner with the Carrier Vector eCool cooling system. In this technological approach, a trailer axle is equipped with an axle generator that feeds electrical energy to a battery pack mounted under the body. Weighing only 320 kg, this energy storage unit supplies power to the all-electric Carrier refrigeration unit with the help of intelligent control electronics, so that this Cool Liner variant also manages without a diesel unit in the cooling system. A 400 V plug-in contact also enables operation of the refrigeration system as well as parallel external charging of the battery via shore power. The operating unit for the system is conveniently positioned on the front wall of the refrigerated body.

To achieve a high level of sustainability, especially for inner-city refrigerated transport, Krone has equipped the Cool Liner with the Carrier Vector eCool cooling system. In this technological approach, a trailer axle is equipped with an axle generator that feeds electrical energy to a battery pack mounted under the body. Weighing only 320 kg, this energy storage unit supplies power to the all-electric Carrier refrigeration unit with the help of intelligent control electronics, so that this Cool Liner variant also manages without a diesel unit in the cooling system. A 400 V plug-in contact also enables operation of the refrigeration system as well as parallel external charging of the battery via shore power. The operating unit for the system is conveniently positioned on the front wall of the refrigerated body.

To achieve a high level of sustainability, especially for inner-city refrigerated transport, Krone has equipped the Cool Liner with the Carrier Vector eCool cooling system. In this technological approach, a trailer axle is equipped with an axle generator that feeds electrical energy to a battery pack mounted under the body. Weighing only 320 kg, this energy storage unit supplies power to the all-electric Carrier refrigeration unit with the help of intelligent control electronics, so that this Cool Liner variant also manages without a diesel unit in the cooling system. A 400 V plug-in contact also enables operation of the refrigeration system as well as parallel external charging of the battery via shore power. The operating unit for the system is conveniently positioned on the front wall of the refrigerated body.

To achieve a high level of sustainability, especially for inner-city refrigerated transport, Krone has equipped the Cool Liner with the Carrier Vector eCool cooling system. In this technological approach, a trailer axle is equipped with an axle generator that feeds electrical energy to a battery pack mounted under the body. Weighing only 320 kg, this energy storage unit supplies power to the all-electric Carrier refrigeration unit with the help of intelligent control electronics, so that this Cool Liner variant also manages without a diesel unit in the cooling system. A 400 V plug-in contact also enables operation of the refrigeration system as well as parallel external charging of the battery via shore power. The operating unit for the system is conveniently positioned on the front wall of the refrigerated body.

HACCP-compliant double-deck guide rails recessed flush into the wall. Horizontal markings on the guide rails facilitate height adjustment of the double-deck beams. Horizontal locking beams are used for rear load securing.

HACCP-compliant double-deck guide rails recessed flush into the wall. Horizontal markings on the guide rails facilitate height adjustment of the double-deck beams. Horizontal locking beams are used for rear load securing.

HACCP-compliant double-deck guide rails recessed flush into the wall. Horizontal markings on the guide rails facilitate height adjustment of the double-deck beams. Horizontal locking beams are used for rear load securing.

Four stainless steel rollers with shock-absorbing cores protect the rear end when docking. They easily compensate for the height of the ramp.

Adapt the ram protection to meet your requirements. You can select the ram protection system, which is optimised for your application, from an extensive modular system.

Carrier eCool unit

To achieve a high level of sustainability, especially for inner-city refrigerated transport, Krone has equipped the Cool Liner with the Carrier Vector eCool cooling system. In this technological approach, a trailer axle is equipped with an axle generator that feeds electrical energy to a battery pack mounted under the body. Weighing only 320 kg, this energy storage unit supplies power to the all-electric Carrier refrigeration unit with the help of intelligent control electronics, so that this Cool Liner variant also manages without a diesel unit in the cooling system. A 400 V plug-in contact also enables operation of the refrigeration system as well as parallel external charging of the battery via shore power. The operating unit for the system is conveniently positioned on the front wall of the refrigerated body.

Double-deck device

HACCP-compliant double-deck guide rails recessed flush into the wall. Horizontal markings on the guide rails facilitate height adjustment of the double-deck beams. Horizontal locking beams are used for rear load securing.

Roll Compression Buffer

Four stainless steel rollers with shock-absorbing cores protect the rear end when docking. They easily compensate for the height of the ramp.

Ram protection concept

Adapt the ram protection to meet your requirements. You can select the ram protection system, which is optimised for your application, from an extensive modular system.