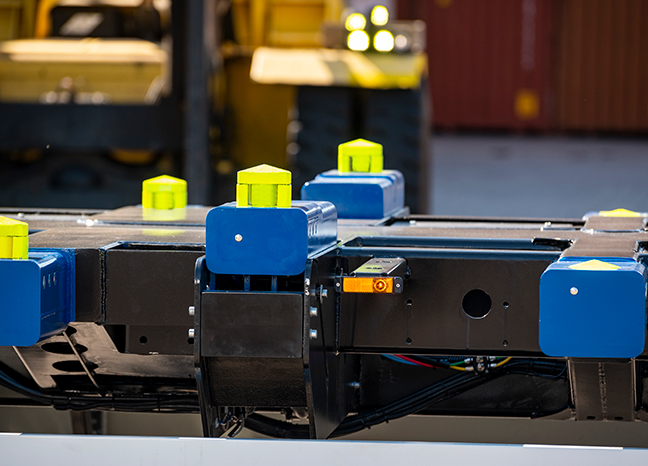

BOX LINER AUTOMATIC

Automatic presetting for containers

- AUTOMATED PRESETTING

- FOR ALL CONTAINERS FROM 20' TO 45'

- SAFE ENVIRONMENT FOR THE DRIVER

- FASTER CONTAINER HANDLING

- AVOIDANCE OF CONTAINER MISSES

The highlight of the innovative Box Liner Automatic is the possibility of automated presetting. Safe and convenient: The driver can adjust the container chassis to all containers from 20' to 45' at the touch of a button from the truck cab.The highlight of the innovative Box Liner Automatic is the option of automated presetting. Safe and convenient: The driver can adjust the container chassis to all containers from 20' to 45' at the touch of a button from the truck cab.

Technical data

Type

SDC 27 eLTU50

King Pin load

14000 kg

Axle load

27000 kg

Perm. total weight

41000 kg

Tare weight

5180 kg

Payload

35300 kg

Axle spread

1410 / 1310 mm

Neck height

130 mm

5th wheel height

1130 mm

Distance kingpin - rear end (40‘)

11250 mm

Always a plus on equipment.